When I choose an auto darkening welding helmet, I notice a clear difference between budget and premium options. Expensive helmets give me a wider field of vision and superior lens clarity, which matters most during detailed welding tasks. I have seen that cheaper helmets can frustrate users due to unreliable sensors or premature lens activation from metal reflections. Electronics in low-cost helmets may fail more often, making safety and work continuity uncertain.

—better quality often comes with a higher price.

In summary, I always find that investing in a high-quality auto darkening welding helmet brings greater clarity, comfort, and peace of mind.

Key Takeaways

- Expensive helmets offer clearer lenses with better materials and top optical ratings, reducing eye strain and improving weld quality.

- Premium helmets provide wider shade ranges and precise controls for better protection and adaptability to different welding tasks.

- Fast and consistent auto-darkening reaction in high-end helmets protects eyes better and increases comfort during long use.

- Certified helmets with CE or ANSI marks ensure reliable safety features like impact resistance and UV/IR protection.

- Comfortable helmets have adjustable, padded headgear and lightweight designs that reduce neck strain and fatigue.

- Durable helmets use strong, heat-resistant materials and have longer-lasting lenses, saving money over time.

- Advanced helmets include digital controls, memory presets, and specialized modes that improve efficiency and versatility.

- Budget helmets suit occasional or hobby use, but professionals benefit from investing in premium helmets for safety and long-term value.

Auto Darkening Welding Helmet Lens Quality and Clarity

Optical Clarity Differences

Lens Material and Manufacturing Standards

When I select a welding helmet, I pay close attention to the lens material and how it is made. Premium helmets use high-purity materials and advanced manufacturing processes. This results in a lens that stays clear and resists impurities. Cheaper helmets often use lower-grade materials, which can introduce tiny imperfections. These imperfections scatter light and make the view less sharp. Over time, I notice that a high-quality lens keeps my eyes comfortable and helps me see the weld pool more clearly.

Clarity Ratings and Certifications (EN379, etc.)

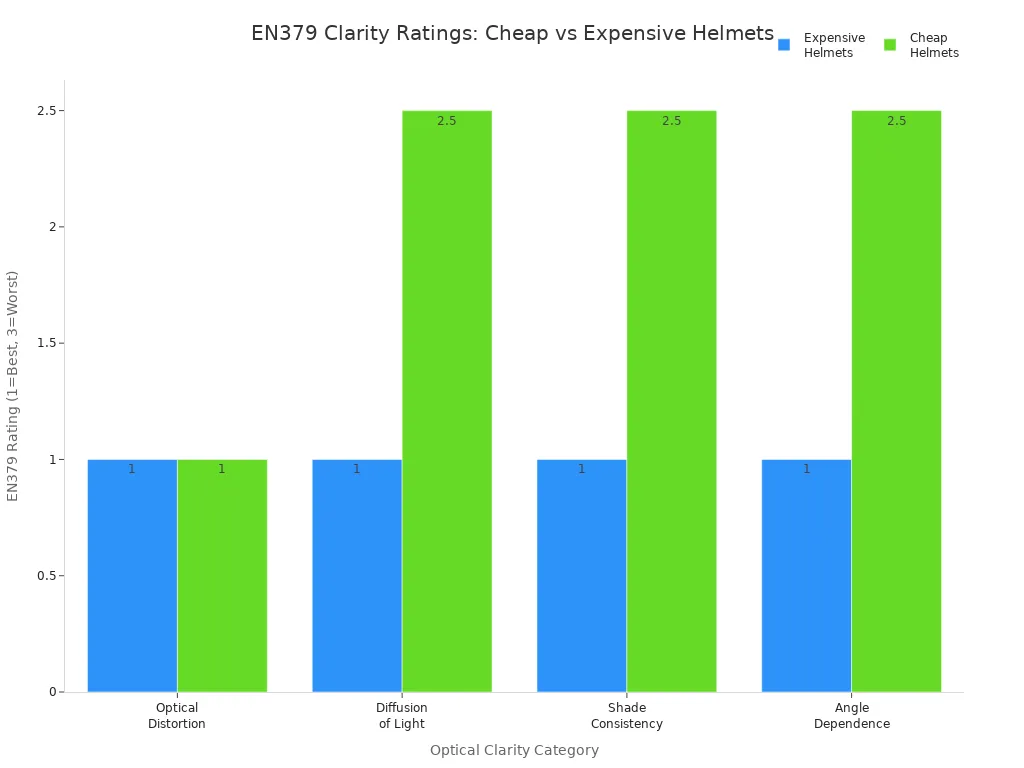

I always check the EN379 optical clarity rating before making a purchase. This standard rates helmets in four categories: optical distortion, diffusion of light, shade consistency, and angle dependence. The best helmets score 1/1/1/1, which means they offer minimal distortion, pure lens material, even shading, and stable performance at different angles. Lower-rated helmets, often found at lower prices, may have issues like blurry images or uneven shading. These problems can cause eye strain and make it harder to focus on the weld.

Here is a comparison table that shows how expensive and cheap helmets perform in each EN379 category:

| EN379 Optical Clarity Category | Rating Scale | Expensive Helmets (Typical) | Cheap Helmets (Typical) | Impact on Welding Experience |

|---|---|---|---|---|

| Optical Distortion (Accuracy of Vision) | 1 (best) – 3 (worst) | 1 | Usually 1 | Expensive helmets have minimal distortion; cheap helmets usually still 1, so distortion is less of an issue. |

| Diffusion of Light (Impurities) | 1 – 3 | 1 | Often 2 or 3 | Cheap helmets may have impurities causing blurry or unclear images, leading to eye strain. |

| Shade Consistency (Luminous Transmittance) | 1 – 3 | 1 | Often 2 or 3 | Cheap helmets show inconsistent shading across the lens, causing bright or dark spots, affecting visibility. |

| Angle Dependence of Shade | 1 – 3 | 1 | Often 2 or 3 | Cheap helmets have shade inconsistencies at angles, causing image stretching, blurriness, and difficulty focusing. |

Note: I find that a 1/1/1/1 helmet gives me a clear, comfortable view and helps me work longer without eye fatigue. For hobby use, a 1/1/1/2 helmet may be enough, but professionals benefit from the best clarity.

Summary:

High-quality lens materials and top EN379 ratings make a big difference in comfort and weld quality. I always choose the best clarity I can afford.

Shade Range and Adjustability

Number of Shade Levels Available

The shade range is another key factor I consider. Most cheap helmets offer a fixed shade or a basic range, such as 4/11. More expensive models provide a wider and more adjustable range5-8/9-13, sometimes including special modes for grinding or cutting. This flexibility lets me match the shade to the welding process, amperage, and material.

| Shade Range | Notes on Features and Adjustability |

|---|---|

| Fixed Shade 4/11 or 4/8-12 | Basic auto-darkening, suitable for budget-conscious buyers |

| 4/9-13 | Adjustable shade, sensitivity and delay controls, solar powered |

| 3/ 9-13 | TrueColor;Combines passive shade 13 filter with auto-darkening LCD, multiple user controls |

| 3/4-9 / 9-13 | TrueColor;Adjustable shade with modes for Grind (3), Cut (4-9), Weld (9-13), advanced controls |

I notice that while both cheap and expensive helmets may cover similar shade ranges, the premium models offer finer adjustability and more user-friendly controls.

Sensitivity and Delay Control Options

I rely on sensitivity and delay controls to fine-tune my helmet’s response. Expensive helmets often provide more precise adjustments. This allows me to set how quickly the lens darkens and how long it stays dark after the arc stops. With a cheap helmet, I sometimes find the controls less responsive or limited in range. This can make it harder to adapt to different welding tasks or environments.

Tip: Adjustable shade, sensitivity, and delay settings help me protect my eyes and improve weld quality by matching the helmet’s performance to the job.

Summary:

A wider shade range and better adjustability give me more control and safety. I always look for helmets with easy-to-use controls and multiple shade options.

Reaction Speed and Consistency

Switching Time Comparison

Reaction speed is critical for eye safety. I have learned that the minimum standard for switching time is about 2/5,000 seconds. Some cheap helmets claim even faster speeds, but I remain skeptical. In my experience, expensive helmets deliver consistent and reliable switching, even if the listed speed is slightly slower. My eyes feel less tired, and I avoid discomfort after long sessions.

Reliability During Use

I trust premium helmets to react the same way every time I strike an arc. Cheap helmets sometimes fail to darken quickly or consistently, especially in bright environments or at odd angles. This inconsistency can lead to eye discomfort or even arc eye. I value the peace of mind that comes from knowing my helmet will protect me every time.

Note: Reliable reaction speed and consistency are essential for both safety and comfort. I always prioritize these features when choosing an auto darkening welding helmet.

Summary:

Fast and reliable switching protects my eyes and keeps me comfortable. I choose helmets that deliver consistent performance, even if they cost more.

Section Summary:

Lens quality and clarity set the foundation for a safe and productive welding experience. I always look for high EN379 ratings, a wide and adjustable shade range, and reliable reaction speed. These features help me work safely, reduce eye strain, and achieve better welds.

Auto Darkening Welding Helmet Safety Features

Certification and Compliance

CE Certification and Its Importance

When I choose a welding helmet, I always check for CE certification. This mark shows that the helmet meets strict European safety standards. CE-certified helmets go through tests for impact resistance, optical clarity, and UV/IR protection. I trust helmets with this certification because they offer reliable protection and consistent performance. For me, the CE mark means the manufacturer follows high-quality production standards and cares about user safety.

ANSI and Other Safety Standards

In the United States, I look for ANSI Z87.1 certification. This standard ensures the helmet protects against high-velocity impacts, optical radiation, and other workplace hazards. Some helmets also meet CSA (Canada) or AS/NZS (Australia/New Zealand) standards. I find that professional-grade helmets often carry multiple certifications, which gives me extra confidence in their safety. Entry-level helmets may not always meet these standards, so I always double-check before buying.

Note: I always recommend checking for CE, ANSI, or other relevant certifications before using any helmet for welding.

Summary:

Certifications like CE and ANSI show that a helmet meets strict safety requirements. I always choose helmets with these marks to ensure maximum protection.

UV/IR Protection Levels

Protection Consistency Over Time

I rely on my helmet to block harmful ultraviolet (UV) and infrared (IR) rays every time I weld. High-quality helmets use advanced lens coatings and materials that maintain their protective properties over years of use. I notice that professional helmets keep their UV/IR protection even after thousands of welding cycles. This consistency helps prevent eye injuries and long-term vision problems.

Risks of Inadequate Protection

If a helmet fails to block UV or IR rays, I risk serious eye damage, including “arc eye” or even permanent vision loss. Cheaper helmets sometimes lose their protective ability as the lens ages or if the auto-darkening function fails. I always make sure my helmet provides full UV/IR protection, even when the lens is in its light state. This way, I know my eyes stay safe, no matter what.

Summary:

Consistent UV/IR protection is essential for eye safety. I trust helmets with proven, long-lasting protection to keep my vision safe during every weld.

Reliability of Auto Darkening Function

Sensor Quality and Placement

I pay close attention to the number and placement of arc sensors in my helmet. Professional-grade helmets usually have four sensors, which gives me better coverage and reduces the chance of sensor obstruction. Some advanced models even use electromagnetic arc sensors, which detect the welding arc even if something blocks the optical sensors. This technology ensures my helmet darkens instantly, protecting my eyes from harmful light.

Here is a comparison table that highlights the differences between entry-level and professional-grade helmets:

| Feature | Entry-Level Helmets | Professional-Grade Helmets |

|---|---|---|

| Number of Sensors | Typically 2 sensors | Usually 4 sensors for better coverage |

| Switching Speed | Around 2/5,000 of a second | Around 1/25,000 of a second (much faster) |

| Sensor Technology | Basic optical sensors | Advanced sensors, including electromagnetic arc sensors |

| Safety Impact | Higher chance of sensor obstruction | Reduced chance of failure and better responsiveness |

I find that more sensors and faster switching speeds lead to higher safety certification rates and better eye protection.

Failure Rates and Associated Risks

I have learned that sensor failure or slow response can expose my eyes to dangerous arc flashes. Common causes of auto-darkening failure include dirty or blocked sensors, battery issues, and sensor malfunction. Premium helmets rarely fail because they use high-quality sensors and fast electronics. Cheaper helmets may lag or fail completely, increasing the risk of eye injury.

Here are some common causes of auto-darkening failure and how I address them:

- Dirty or obstructed sensors can cause false triggers or delays.

- Battery depletion or failure may stop the lens from darkening.

- Sensor malfunction sometimes requires professional service.

To keep my helmet working reliably, I follow these steps:

- I clean the sensors inside and outside the helmet to remove dirt, spatter, or fingerprints.

- I check the battery charge level regularly.

- I make sure the helmet sits properly on my head.

- If problems continue after cleaning and battery replacement, I seek professional service for the lens module.

Tip: Regular maintenance helps prevent most auto-darkening failures and keeps my eyes safe.

Summary:

Reliable sensors and fast switching protect my eyes from arc flashes. I always maintain my helmet and choose models with advanced sensor technology for peace of mind.

Section Summary:

Safety features set professional helmets apart from entry-level models. I always check for certifications, consistent UV/IR protection, and reliable auto-darkening performance. These features help me work confidently and protect my eyes from harm.

Auto Darkening Welding Helmet Comfort and Fit

Headgear Quality and Adjustability

Padding, Support, and Adjustment Mechanisms

When I select an auto darkening welding helmet, I always examine the headgear first. Comfort starts with the right padding and support. Premium helmets often feature soft sweatbands that absorb perspiration, keeping my forehead dry during long jobs. I appreciate multi-adjustable headgear because it lets me fine-tune the fit for stability and comfort. Ratchet mechanisms make it easy to adjust tightness, even with gloves on. Some models add extra neck padding, which helps during extended use.

| Feature | Description |

|---|---|

| Lightweight construction | Helmets weigh as little as 500 grams, reducing neck strain. |

| Soft sweatband | Absorbs sweat and enhances comfort. |

| Multi-adjustable headgear | Allows precise fit and stability. |

| Comfort neck padding | Improves comfort for long sessions. |

| Ratchet mechanism | Enables quick, precise adjustment. |

| Adjustable airflow outlets | Directs air to the forehead for better ventilation. |

| Air distribution system | Dual air streams optimize clean air supply for breathing comfort. |

Tip: I replace sweatbands regularly to maintain hygiene and comfort.

Impact on Long-Term Wear

I notice that well-designed headgear makes a huge difference during long welding sessions. Helmets with proper padding and easy adjustments reduce pressure points and prevent headaches. When my helmet fits well, I can focus on my work instead of constant readjustment. I find that comfortable headgear encourages me to keep my helmet on, which improves safety and productivity.

Summary:

Quality headgear with good padding and adjustability keeps me comfortable and focused, especially during long shifts.

Weight and Balance

Materials Used in Construction

The materials used in an auto darkening welding helmet directly affect its weight and balance. I prefer helmets made from lightweight plastics or composite materials. These materials keep the helmet light without sacrificing durability. Balanced construction ensures the helmet does not tip forward, which helps me maintain good posture.

Effect on Neck Strain and Fatigue

I have experienced neck strain from heavy helmets in the past. Biomechanical studies show that heavier helmets increase compression forces on the neck, raising the risk of chronic pain. Lighter helmets with improved balance reduce torque on my neck, making it easier to weld for hours. Flexible, ergonomic headgear with comfort cushions supports all-day wear and minimizes fatigue. Some advanced helmets even distribute weight to counterbalance front-heavy lenses, further reducing strain.

- Lighter helmets decrease fatigue and neck pain.

- Well-balanced designs help me maintain proper posture.

- Comfortable helmets encourage longer, safer use.

Summary:

Choosing a lightweight, balanced helmet helps me avoid neck strain and stay productive throughout the day.

Ergonomics and Ventilation

Breathability and Heat Management

Welding can get hot, so I value helmets with good ventilation. High-end models often include adjustable airflow channels that let me direct air toward my face or visor. This feature keeps me cool and prevents my lens from fogging. Some helmets offer dual air streams, which optimize clean air supply and enhance comfort. I also look for padding and sweatbands that help manage heat and moisture.

Design for Extended Use

Ergonomic design matters when I spend hours under the hood. Multiple adjustment points, including tilt and forward-backward settings, let me find the best viewing angle and maintain good posture. Some helmets integrate powered air-purifying respirators, providing a steady flow of filtered air for extra comfort and safety. Replaceable filters and long battery life make these features practical for daily use.

- Adjustable airflow channels improve comfort in hot conditions.

- Ergonomic adjustments help me maintain good posture.

- Advanced ventilation systems support long, safe welding sessions.

Summary:

Ergonomic features and effective ventilation keep me comfortable and safe, even during extended welding projects.

Section Summary:

Comfort and fit play a crucial role in my choice of an auto darkening welding helmet. Quality headgear, lightweight materials, and ergonomic ventilation features help me work longer and safer. I always prioritize these aspects to protect my health and improve my welding performance.

Auto Darkening Welding Helmet Durability and Build Quality

Shell Materials and Construction

Use of Primary vs. Recycled Materials

When I examine welding helmets, I notice that the shell material plays a major role in durability. Premium helmets often use high-quality materials like polyamide (nylon), fiberglass, polycarbonate, metal, or advanced composites. These materials offer better strength and longevity. Budget helmets usually rely on more basic plastics or recycled materials. While these keep costs down, they do not provide the same level of protection or comfort. I find that premium shells feel sturdier and last longer, especially in demanding environments.

Impact and Heat Resistance

The ability of a helmet to withstand impacts and high temperatures is crucial for safety. I have compared different materials and their performance:

| Material Type | Cost Category | Impact Resistance | Heat Resistance | Durability & Notes |

|---|---|---|---|---|

| ABS Plastic | Cheap | Good rigidity, less durable | Poor thermal conductor | Lightweight, economical, less chemical resistant |

| PP | Cheap | Weaker structurally, moderate durability | Moderate | Durable, chemical resistant, but not as strong |

| PA | Expensive | Highly impact-resistant | Withstands high temperatures | Lightweight, durable, more expensive |

| Carbon Fiber | Expensive | Superior impact and vibration resistance | Highly resistant to heat | Exceptionally lightweight, very strong, premium cost |

I always choose helmets with PA or carbon fiber shells for the best protection. These materials handle drops, sparks, and heat much better than basic plastics.

Tip: Investing in a helmet with advanced materials means better safety and longer service life.

Summary:

Premium helmets use stronger, more heat-resistant materials, which leads to better protection and durability. Budget helmets focus on cost, often sacrificing long-term performance.

Lens Durability and Longevity

Resistance to Scratches and Cracks

Lens durability matters to me because scratches or cracks can affect visibility and safety. Expensive helmets use high-grade coatings and tougher lens materials. These resist scratches from spatter and cleaning. Cheaper helmets may develop marks or cracks more quickly, especially if I use them daily or in rough conditions. I always clean my lens gently and replace outer covers as needed to extend its life.

Expected Lifespan in Real-World Use

From my experience and what I have learned from other welders, the lifespan of a helmet lens varies greatly:

| Feature | Expensive Helmets (e.g., Speedglas) | Cheap Helmets |

|---|---|---|

| Average Lifespan | 5 to 10+ years | 1/2 to 2 years |

| Lens Performance | Consistent auto-darkening | Slower, inconsistent |

| Replaceability | Modular parts, easy to replace | Often need full replacement |

| Maintenance Impact | Lasts longer with care | Frequent replacements |

Many welders report using premium helmets for over 5 years with only minor part replacements. I have seen cheap helmets wear out in just a few monthes, especially if used often.

Summary:

Premium helmet lenses last much longer and maintain performance with proper care. Cheaper lenses may need frequent replacement, increasing long-term costs.

Quality Control and After-Sales Support

Manufacturing Standards and Defect Rates

I trust helmets from brands with strict quality control. Premium manufacturers follow high standards, which means fewer defects and more reliable products. They test each helmet for durability, impact resistance, and lens performance. Budget helmets may not go through such rigorous checks, so I sometimes see higher defect rates or inconsistent quality.

Warranty and Customer Service

Warranty and support make a big difference for me. Premium helmets usually come with longer warranties and responsive customer service. If I have an issue, I can get replacement parts or repairs quickly. Budget helmets may offer limited support, making it harder to fix problems or get help.

Note: Good after-sales support gives me peace of mind and protects my investment.

Summary:

Strict quality control and strong after-sales support set premium helmets apart. I always consider warranty and service when choosing a helmet.

Section Summary:

Durability and build quality depend on the materials, lens strength, and manufacturer support. Premium helmets use advanced materials, last longer, and come with better service. Budget helmets focus on affordability but may require more frequent replacement. I always weigh these factors to ensure safety and value.

Auto Darkening Welding Helmet Extra Features

Advanced Controls and Customization

Grind Mode and Cut Mode Availability

I value helmets that offer specialized modes. Many high-end models include:

- Weld mode with a shade range of 8–13 for standard welding.

- Cut mode with a shade range of 5–8, ideal for plasma or oxy-fuel cutting.

- Grind mode at shade 3, which protects my eyes during grinding without full darkening.

- External grind mode buttons for quick access.

These modes let me adapt the helmet to different tasks without removing it or changing equipment.

Suitability for Different Welding Tasks

Specialized modes expand the helmet’s functionality. I can use the same helmet for welding, cutting, and grinding. Adjustable shade levels and advanced filters improve clarity and safety. Ergonomic designs and adjustable headgear keep me comfortable during long sessions. Features like airflow control also help maintain comfort and safety.

Tip: Versatile helmets with multiple modes save me time and reduce the need for extra gear.

Summary:

Specialized modes make my helmet more adaptable. I can handle a variety of tasks efficiently and safely with one piece of equipment.

Technology Upgrades in Premium Models

True Color Technology and Viewing Experience

True Color technology stands out in premium helmets. This feature enhances the clarity and color accuracy of the viewing area. I see more natural colors, which helps me distinguish the weld pool and base material. The Tynweld Infinity helmet TN360-ADF9120, for example, offers a large viewing area and superior optical clarity. This technology reduces eye strain and improves my ability to produce high-quality welds.

Power Sources: Solar vs. Battery Options

Power source options affect reliability and maintenance. I have used both solar-powered and battery-powered helmets. Here is a comparison:

| Aspect | Solar Powered Helmets | Battery Powered Helmets |

|---|---|---|

| Power Source | Photovoltaic cells convert sunlight to electrical energy | Rechargeable or disposable batteries |

| Maintenance Needs | No battery replacements needed, reducing maintenance cost | Requires regular battery replacements and maintenance |

| Reliability | More reliable in harsh conditions (extreme heat/cold) | Consistent performance even in low-light or indoor settings |

| Environmental Impact | Environmentally friendly, no battery waste | Battery waste generated |

| Portability | Dependent on sunlight availability | Portable, works without sunlight |

| Market Trend | Significant market share due to low maintenance and reliability | Expected higher growth due to convenience and tech advances |

I check my helmet regularly for dust, debris, or damage. Proper storage and following manufacturer guidelines help me maximize reliability and lifespan.

Note: Choosing the right power source depends on my work environment and maintenance preferences.

Summary:

Premium helmets offer advanced technologies like True Color and flexible power options. These upgrades improve my viewing experience and reduce maintenance hassles.

Section Summary:

Extra features in premium helmets—such as digital controls, memory presets, specialized modes, and advanced technologies—make my work safer, more efficient, and more comfortable. I always consider these features when I want the best performance and versatility from my welding helmet.

Auto Darkening Welding Helmet Value for Money

When a Cheap Auto Darkening Welding Helmet Is Enough

Occasional Use and Hobby Projects

I often recommend a budget-friendly helmet for hobbyists or those who weld only occasionally. In my experience, entry-level helmets work well for light tasks such as MIG welding, TIG welding, tack welding, grinding, cutting, and general repairs around the house. These helmets provide automatic optical response, so I do not need to lift the helmet repeatedly. This feature reduces fatigue and helps me focus on precision.

- Many hobbyists value comfort, ease of use, and reliable protection over advanced features.

- Some helmets include modes for plasma cutting and grinding, which I find especially useful for home projects.

- Adjustable headgear and side vision features improve usability for occasional users.

For hobby welders and welders-in-training, I find that a basic auto darkening welding helmet offers a good balance of affordability and essential protection.

Budget Constraints and Entry-Level Needs

When my budget is tight, I look for helmets that deliver core safety features without unnecessary extras. Moderate pricing and simple adjustment mechanisms make these helmets accessible. I appreciate that even entry-level models now offer variable shade ranges and quick reaction times, supporting a range of welding and grinding applications. For those just starting out, these helmets provide a practical and cost-effective solution.

Tip: If you weld only a few times a month, a budget helmet with essential features can meet your needs without overspending.

Summary:

For occasional use or hobby projects, a basic helmet provides comfort, convenience, and reliable protection at a reasonable price.

When to Invest in an Expensive Auto Darkening Welding Helmet

Professional, Daily, or High-Risk Use

When I weld every day or work in high-risk environments, I invest in a premium helmet. Professional-grade helmets offer advanced headgear with multiple contact points, distributing weight evenly and reducing neck strain. Fast-switching lenses protect my eyes and improve my precision, which boosts productivity. Permanent UV and IR filters give me peace of mind, knowing my eyes stay protected even if the auto-darkening feature fails.

- Premium helmets often include four sensors for better coverage and safety.

- Features like extra-large viewing areas and digital interfaces save me time and enhance control.

- I rely on these helmets for specialized tasks and long welding sessions.

Long-Term Savings and Productivity Gains

Although the upfront cost is higher, I see real savings over time. Premium helmets last longer, require fewer replacements, and reduce downtime due to discomfort or maintenance. Ergonomic designs and lightweight materials let me weld longer with less fatigue. Customizable fit and better ventilation keep me comfortable, which means I can work more efficiently.

| Feature | Benefit |

|---|---|

| TRUECOLOR Technology | Superior clarity, less eye strain |

| HG6 Headgear | All-day comfort, reduced pressure |

| 5 Year Warranty | Lower replacement costs, protects investment |

Summary:

For daily or professional use, a premium helmet delivers better safety, comfort, and long-term value, making it a smart investment.

Cost vs. Benefit Analysis

Balancing Price, Safety, and Performance

When I compare helmets, I weigh the price against the features and protection offered. Auto darkening helmets provide dynamic protection by adjusting lens shade automatically, which improves safety and convenience. Features like sensitivity and delay controls, battery indicators, and multiple sensors enhance reliability. I also consider comfort features such as adjustable headgear and lightweight materials.

- Define your welding needs and environment.

- Choose materials with good optical clarity and durability.

- Verify compliance with safety standards.

Making the Right Choice for Your Needs

I always match my helmet choice to my welding frequency, environment, and safety requirements. For light, occasional work, a budget helmet meets my needs. For frequent or demanding tasks, I invest in a premium model to maximize safety and productivity. I find that balancing price, safety, and performance ensures I get the best value for my money.

Note: —better quality often comes with a higher price, but the right helmet pays off in safety and comfort.

Summary:

A careful cost-benefit analysis helps me choose the right helmet for my needs, ensuring I stay safe and productive without overspending.

I always weigh my options before choosing a helmet. Expensive models give me better clarity, comfort, and advanced features. These helmets last longer and keep me safer during daily or professional welding. Cheaper helmets work for light-duty or occasional projects, but I notice they may not last as long. I recommend matching your helmet choice to your welding habits, safety needs, and budget. Safety and comfort should always come first.

Remember: The right helmet makes every weld safer and more enjoyable.

FAQ

What is the main difference between cheap and expensive auto darkening welding helmets?

I notice that expensive helmets offer better lens clarity, faster reaction times, and more advanced features. Cheap helmets usually focus on basic protection and may lack comfort or durability.

How do I know if a welding helmet meets safety standards?

I always check for certifications like CE or ANSI Z87.1 on the helmet. These marks show that the helmet passed strict safety tests for impact resistance and optical protection.

Can I use a cheap helmet for professional welding?

I do not recommend using a cheap helmet for daily or high-risk welding. Professional work demands reliable sensors, durable materials, and advanced comfort features that budget models often lack.

Do expensive helmets last longer than cheap ones?

From my experience, premium helmets last many years with proper care. They use stronger materials and better electronics. Cheap helmets may need replacement after a few years of regular use.

Are digital controls worth the extra cost?

I find digital controls very helpful. They let me adjust settings quickly and save presets for different tasks. This feature saves time and improves accuracy during complex welding jobs.

What should I look for in helmet comfort?

I look for adjustable headgear, soft padding, and lightweight materials. These features reduce neck strain and help me stay comfortable during long welding sessions.

Is True Color technology important?

True Color technology gives me a clearer, more natural view of the weld area. This helps me see details better and reduces eye fatigue, especially during long projects.

Summary:

I always choose my welding helmet based on how often I weld, my safety needs, and my comfort preferences. Premium helmets deliver better performance and protection, while budget models suit occasional or hobby use. Safety and comfort always come first in my decision.

Post time: Aug-01-2025