I trust my auto darkening welding lens because it never fails me, even in the toughest conditions. TRUE COLOR technology, which we pioneered, gives me crystal-clear visibility and reduces eye strain. This innovation helps me see welds accurately and stay safe, while the lens’s rapid response and robust build deliver unmatched reliability.

Key Takeaways

- TRUE COLOR technology offers clear, natural vision that reduces eye strain and helps welders produce higher-quality work safely and comfortably.

- Auto darkening welding lenses provide instant eye protection with adjustable settings, ensuring reliable performance across different welding types and conditions.

- Choosing a durable, certified lens with ergonomic design improves comfort during long sessions and guarantees lasting safety and reliability on the job.

Why This Auto Darkening Welding Lens Stands Out

TRUE COLOR Technology Advantage

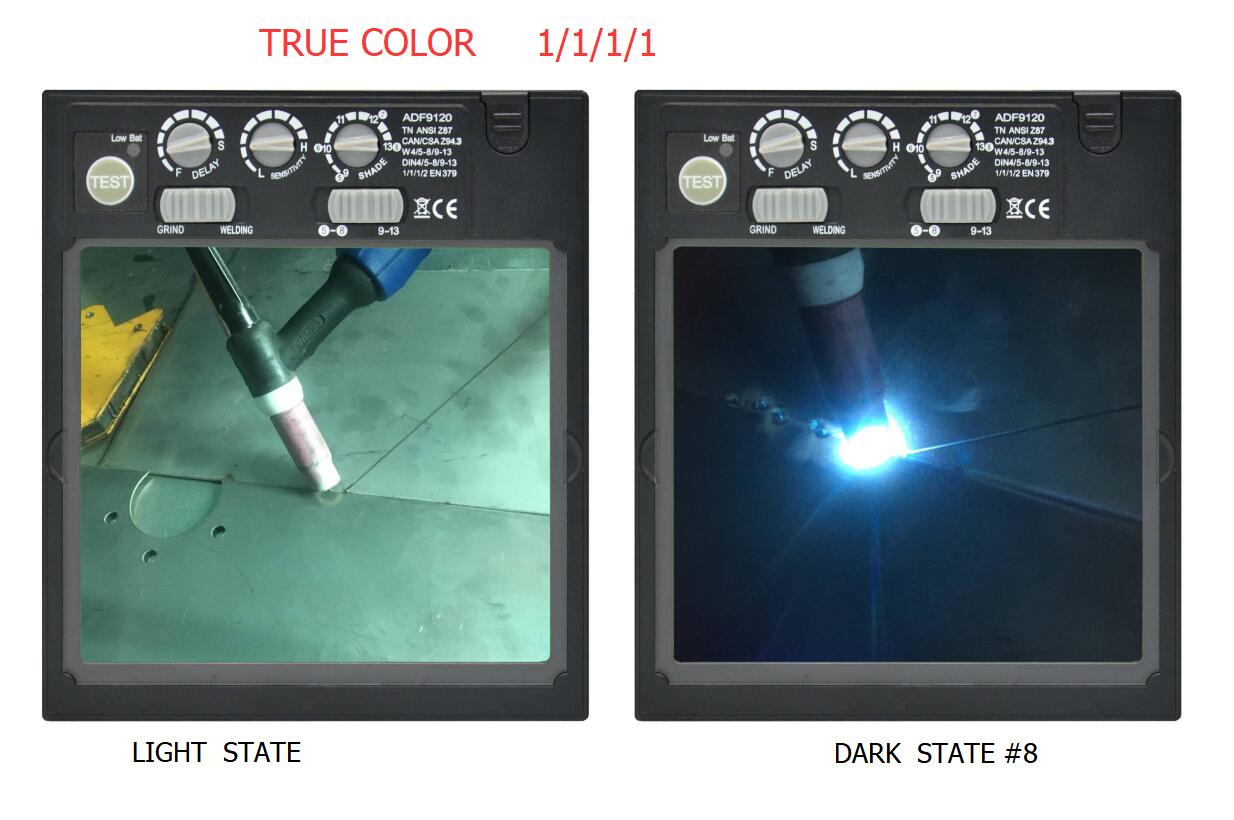

When I use my auto darkening welding lens with TRUE COLOR technology, I notice the difference immediately. The clarity of the weld puddle stands out, and my eyes feel less strained, even after hours of work. TRUE COLOR is our trademark. Many companies have issued this technology, but our TRUE COLOR is real TRUE COLOR delivering a truly natural view of the welding environment.

I rely on this lens to help me see every detail, from the smallest weld bead to the subtle changes in metal color. This clarity boosts my confidence and allows me to produce higher-quality welds. Industry experts agree that true color technology, especially when paired with a wide viewing area, reduces eye fatigue and improves weld quality. The demand for safety, comfort, and productivity continues to drive the adoption of this advanced feature.

Here’s how TRUE COLOR technology impacts my daily welding experience:

| Aspect | Benefit |

|---|---|

| Eye Strain Reduction | Clearer weld puddle visibility means less eye fatigue during long shifts |

| Weld Quality Improvement | Enhanced visibility leads to more precise, higher-quality welds |

| Safety & Productivity | Less fatigue and better protection increase my efficiency and safety |

| Market Trend | TRUE COLOR is now a must-have for professionals in demanding industries |

Proven Reliability and Safety

I trust my auto darkening welding lens because it never lets me down, even in the most challenging environments. The lens responds instantly, darkening in less than a blink to protect my eyes from harmful UV and IR radiation. I appreciate that this protection remains active, even when the lens is not darkened, so I never worry about accidental arc flashes.

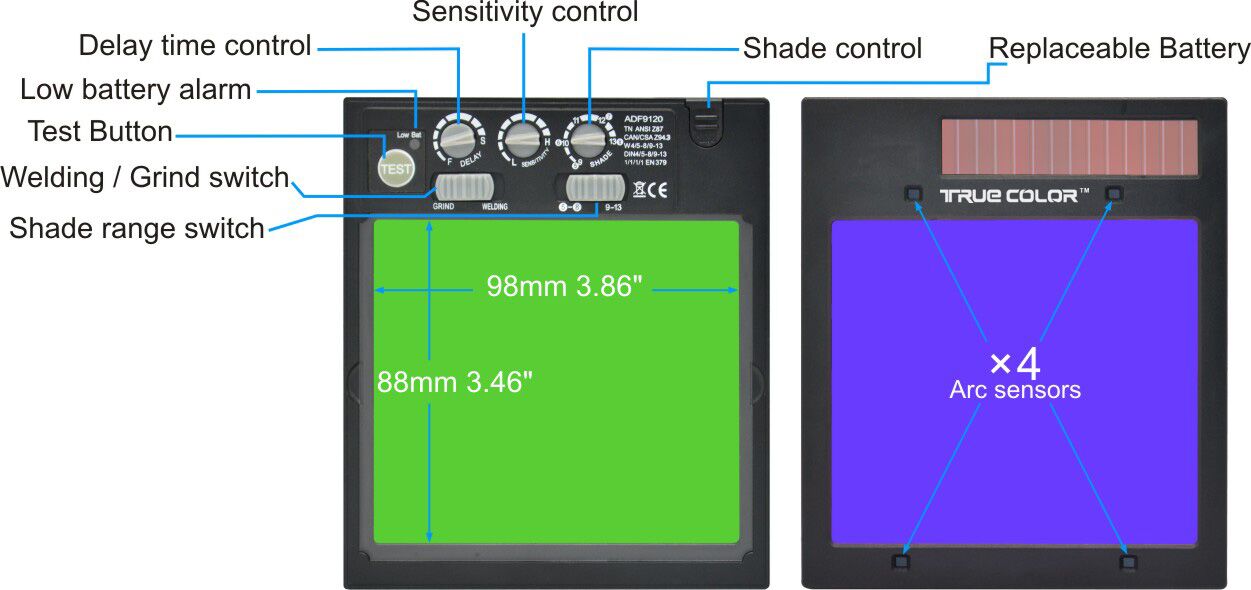

- The lens features multiple arc sensors for reliable activation, even at low amperage.

- Adjustable shade levels and sensitivity controls let me tailor protection for any welding task.

- The helmet’s design reduces neck strain, since I no longer need to flip it up and down between welds.

Regular inspection and maintenance keep my lens in top condition. I check for lens clarity, auto-darkening function, and helmet integrity before every job. I replace my helmet every two years or immediately if I notice any damage. This routine ensures my equipment always meets safety standards and performs reliably.

Industry Certifications and Reputation

I choose equipment that meets the highest industry standards. My auto darkening welding lens carries the CE certification, which assures me of its quality and safety. Leading lenses also meet ANSI Z87.1 (USA) and EN379 CE (Europe) standards. These certifications guarantee protection against impact, optical radiation, and flying debris.

| Certification | Region | What the Certification Entails |

|---|---|---|

| ANSI Z87.1 | USA | Ensures passive eye and face protection, regulates clarity and protection balance |

| EN379 CE | Europe | Tests auto-darkening filter quality, UV/IR protection, and optical clarity |

Industry organizations and professionals consistently rate the best auto darkening welding lens highly. The American Welding Society praises advanced lens technologies for their superior visibility, comfort, and safety. Market reports show that welders expect features like enhanced optical clarity and smart technology integration. I see these expectations reflected in my daily work, where reliability and performance matter most.

Auto Darkening Welding Lens In-Depth Review

Performance Across Welding Applications

I rely on my auto darkening welding lens for every welding job, whether I am working with MIG, TIG, or Stick welding. Each process demands different performance characteristics, and my lens adapts seamlessly. High optical clarity is crucial for TIG welding, where I need to see the finest details and control the weld pool with precision. My lens delivers a natural, distortion-free view, which reduces eye fatigue and helps me maintain accuracy.

Reaction time matters just as much. My lens darkens almost instantly—within 1/25,000 of a second—so my eyes stay protected from sudden arc flashes. I adjust the shade range depending on the task: higher shades for high-amperage welding and lower shades for delicate TIG work. Sensitivity and delay controls let me fine-tune the lens for different lighting conditions and amperage levels. This flexibility keeps my eyes comfortable and safe, even during long shifts.

| Performance Metric | Description | Relevance to Welding Types (MIG, TIG, Stick) |

|---|---|---|

| Shade Range | Variable shade levels typically from 9-13; some models 5-8/9-13 for grinding/cutting | MIG: 10-13 depending on wire size and amperage; TIG: 9-12 with emphasis on clarity; Stick: 9-13 depending on electrode size |

| Reaction Time | Time for lens to darken upon arc detection; typically 0.05 to 0.1 milliseconds | Critical for all welding types to protect eyes instantly; premium helmets offer faster response times |

| Delay and Sensitivity Settings | Controls how long lens stays dark after arc stops; sensitivity adjusts for arc brightness | Sensitivity important for low-amperage TIG and high-amperage Stick welding |

| Optical Clarity (EN379) | 1/1/1/1 or 1/1/1/2 | Especially important for TIG welding requiring precision; also benefits MIG and Stick for clear arc visibility |

| ANSI Z87.1 Compliance | Ensures continuous UV/IR protection and impact resistance | Mandatory for workplace safety across all welding types |

| DIN Shade Classification | German standard classifying light filtering levels from shade 3 to 14 | Provides standardized shade recommendations by amperage and welding process (e.g., Stick 9-13, MIG 10-13, TIG 9-12) |

| Sensor Accuracy and Quantity | Multiple sensors (2 or 4) improve arc detection reliability | Important for all welding types to prevent false triggering and ensure consistent lens darkening |

| Lens Coating Technologies | Gold-coated and other coatings improve clarity and durability | Enhances performance especially in precision TIG and high-intensity MIG/Stick welding |

Tip: I always check my lens settings before switching between welding types. This habit ensures I get the best protection and visibility for each job.

When I weld in high-amperage or low-light scenarios, I appreciate the adjustable shade range. I set the lens to shade #13 or higher for maximum protection during heavy-duty welding. For low-amperage TIG work, I use a lighter shade to avoid over-darkening and reduce eye strain. Sensitivity and delay controls help me adapt to changing light conditions, so I never miss a detail.

- Adjustable shade ranges suit different amperages and welding types.

- Higher shade levels protect my eyes during high-amperage welding.

- Sensitivity and delay controls let me fine-tune performance for any scenario.

- Fast response times and smooth shade switching keep my vision clear and comfortable.

Durability and Build Quality

Durability stands at the core of my expectations for any auto darkening welding lens. I trust my lens because it uses strong, shock-resistant, and flame-resistant materials. The helmet shell, made from polypropylene, shields me from impacts, heat, and sparks. This construction meets strict industry standards like ANSI Z87.1, EN379 CE, and CSA Z94.3, so I know I am protected in hazardous environments.

Manufacturers design these helmets to be lightweight yet sturdy. I can wear my helmet for hours without neck or shoulder strain, thanks to the balanced build and adjustable headgear. The breathable padding adds comfort, which helps me stay focused on my work. Advanced auto-darkening filters, powered by solar cells and lithium batteries, ensure the lens responds reliably every time I strike an arc.

Note: I always inspect my helmet for cracks or wear before each use. Regular checks help me catch issues early and extend the life of my equipment.

Key Features to Look for in an Auto Darkening Welding Lens

Reaction Time and Sensitivity

When I select an auto darkening welding lens, I always check the reaction time and sensitivity. Fast reaction time protects my eyes from sudden arc flashes. The industry standard is at least 0.0001 seconds, but our some top models can reach 0.00015 seconds. Adjustable sensitivity settings help me fine-tune the lens for different welding environments and processes. I rely on these features to keep my eyes safe and comfortable.

Shade Range and Adjustability

I need a lens that adapts to every welding process. The best auto darkening welding lenses offer a wide shade range, usually adjustable from shade 9 to 13. This flexibility lets me work with low or high amperage applications. I use a simple knob to select the right darkness level for each task. Modern lenses also provide delay and sensitivity adjustments, which help me stay comfortable and protected during any welding job.

- Variable shade ranges suit MIG, TIG, Stick, and plasma cutting.

- Shade adjustment ensures proper eye protection for every process.

- Delay and sensitivity controls improve usability and comfort.

Comfort and Ergonomics

Long welding sessions demand comfort. I choose helmets with lightweight designs to reduce neck strain. Ergonomic headgear with multiple adjustment points gives me a secure fit. Padding and sweatbands keep me comfortable, even in hot conditions. Balanced weight distribution prevents fatigue, and external controls let me adjust settings without removing my helmet. A large viewing area means I move my head less, which supports good posture.

Tip: I always look for helmets with adjustable headgear and breathable padding for maximum comfort.

Optical Clarity and Viewing Area

Clear vision is essential for quality welds. I prefer lenses with high optical clarity ratings, such as 1/1/1/1 or 1/1/1/2, which meet or exceed industry standards. A large viewing area, like the 3.9″ x 2.64″ window on the Eastwood L6700, helps me see more of my work without moving my head. TRUE COLOR technology gives me realistic color perception, making it easier to spot weld details and defects. Certifications like CE and ANSI assure me of quality and safety.

Real-World Performance of Auto Darkening Welding Lens

User Experiences in Demanding Scenarios

User Experiences in Demanding Scenarios

I have seen my auto darkening welding lens perform exceptionally well in tough industrial settings. In manufacturing plants, welders like me rely on these lenses to boost productivity and reduce injuries. I remember a project where our team switched to lenses with true color technology. The difference was immediate. We worked faster, and our eyes felt less tired at the end of each shift. Fewer injuries occurred because the lens responded instantly to every arc.

On large construction sites, I noticed that continuous eye protection became critical. My lens, equipped with neck and shoulder drapes, shielded me from sparks and debris. Even when lighting conditions changed, I never lost visibility or protection. Professional welders around me reported similar experiences, praising the improved safety and work quality.

| Case Study | Industrial Environment | Key Benefits | Description |

|---|---|---|---|

| CS1: Manufacturing Plant | Manufacturing | Increased productivity, Reduced injuries | Implementation of auto darkening welding goggles with true color technology led to more efficient work and fewer welding-related injuries among the welding team. |

| CS2: Construction Project | Large construction site | Enhanced safety, Continuous eye protection, Additional physical protection | Use of goggles with neck and shoulder drapes improved safety by protecting against sparks and debris, ensuring continuous eye protection in varying light conditions. |

Where This Lens Excels Most

I find that my lens excels in environments where safety and clarity cannot be compromised. During long welding sessions, the true color technology keeps my vision sharp and reduces fatigue. The lens adapts quickly to changing light, which is essential when I move between indoor and outdoor work. Hobbyists appreciate the ease of use, while professionals value the consistent performance. Whether I am tackling a complex fabrication job or a quick repair, my auto darkening welding lens never lets me down.

_看图王.png)

Maintenance and Longevity of Auto Darkening Welding Lens

Cleaning and Care Best Practices

I always treat my auto darkening welding lens as a precision tool. Keeping it in top shape starts with regular inspection and gentle cleaning. Here’s my routine for maintaining peak performance:

- I inspect the lens for scratches or smudges before every use. Even small marks can affect how the lens darkens and may compromise my eye protection.

- I use a soft, clean cloth to wipe the lens. I never use harsh chemicals because they can damage the surface.

- I store my helmet in a dry, safe place. This prevents accidental drops or exposure to moisture that could harm the electronics.

- I check the batteries before each job. For solar-powered helmets, I make sure the solar panels stay clean for reliable operation.

- I pay attention to the environment. In dusty or oily shops, I clean the helmet more often to keep the lens and sensors clear.

Tip: Consistent care not only keeps my vision sharp but also ensures my safety on every weld.

Maximizing Lens Lifespan

I want my equipment to last, so I avoid common mistakes that can shorten its life. I never neglect cleaning, and I always handle my helmet with care. Here are the key factors I focus on:

- Quality matters. I choose helmets with high-grade lenses and electronics for longer durability.

- I avoid exposing my helmet to extreme heat or cold, which can damage the lens or reduce battery life.

- I replace worn parts, like headgear or batteries, as soon as I notice issues.

- I adjust the helmet for a proper fit and test the settings before each use.

- I store my helmet away from direct sunlight and heavy objects.

From my experience and what manufacturers report, a high-quality auto darkening welding lens can last three to five years. Regular cleaning, careful storage, and timely replacement of parts help me get the most out of my investment.

I trust my auto darkening welding lens for its instant darkening, wide viewing area, and unmatched comfort. Welders benefit from advanced sensors, ergonomic design, and easy adjustments.

- Enhanced safety and clarity

- Reliable performance for every application

- Professional-grade value and durability

Choose with confidence.

FAQ

How do I know when to replace my auto darkening welding lens?

I check for scratches, slow reaction, or inconsistent darkening. If I see any of these signs, I replace the lens right away.

Can I use my auto darkening welding lens for grinding or cutting?

I switch my lens to grind mode for grinding or cutting tasks. This setting keeps my eyes safe and gives me a clear view.

What makes TRUE COLOR technology different from other lens technologies?

I see natural colors and sharper details with TRUE COLOR. This technology reduces eye strain and helps me work more efficiently.

Post time: Jul-28-2025