When I use an auto darkening lens, I trust its advanced sensors to react instantly to welding arcs. Unlike passive lenses, which stay dark and limit my vision, this technology lets me see clearly while staying protected. I notice less fatigue and better comfort during long welding sessions.

Key Takeaways

- Auto darkening lenses use sensors to detect welding arcs instantly and darken the lens quickly, protecting your eyes from harmful light and radiation.

- These lenses block nearly all UV and IR rays at all times, even when clear, ensuring continuous eye safety during welding and preparation.

- Regularly test and maintain your helmet by checking sensors, cleaning lenses, and replacing batteries to keep your eyes safe and your equipment reliable.

Auto Darkening Lens Protective Mechanism

.png)

Sensors Detect Harmful Light

When I put on my welding helmet, I rely on the sensors built into the auto darkening lens to keep my eyes safe. These sensors sit at the front of the helmet and constantly scan for the intense light and radiation produced by the welding arc. I have noticed that higher-quality helmets often include four or more sensors, which gives me extra confidence that my eyes stay protected even if I move my head or something blocks part of the helmet.

The sensors react to the brightness of the welding arc, not just any light. They send an electronic signal to the lens, which triggers the darkening process almost instantly. This rapid response means my eyes never get exposed to dangerous flashes.

Here’s a quick overview of how these sensors work:

| Aspect | Details |

|---|---|

| Sensor Type | Light sensors positioned near the lens to detect intense welding arc light |

| Sensor Quantity | Varies by helmet model; higher-end helmets often have 4 or more sensors for better coverage |

| Sensitivity | High-sensitivity sensors that differentiate welding arc light from ambient light sources |

| Reaction Time | Lens darkens within 0.1 to 0.5 milliseconds, ensuring immediate protection |

| Function | Sensors send electronic signals to the Auto-Darkening Filter (ADF) to adjust lens shade |

| Purpose | Protects eyes from harmful UV and IR radiation emitted during welding |

UV/IR Filter Provides Constant Protection

I trust my auto darkening lens to protect my eyes from ultraviolet (UV) and infrared (IR) radiation at all times. Even when the lens appears clear, multiple metallic layers inside the lens block nearly 100% of harmful UV and IR rays. This protection does not depend on the lens darkening; it works continuously, whether I am welding or not.

I feel reassured knowing that my helmet meets strict industry standards like ANSI Z87.1 and CSA Z94.3. These certifications guarantee that the lens provides reliable UV and IR protection, just like traditional passive helmets.

Liquid Crystal Cells Adjust the Shade

The real magic happens inside the lens with the liquid crystal cells. When the sensors detect the welding arc, they send a signal that applies voltage to these cells. The liquid crystals then twist and realign, changing how much light passes through the lens. I see the lens darken almost instantly—usually within 1/25,000 of a second—so my eyes never feel the strain of a sudden flash.

- The lens can adjust from a light shade (around 3 or 4) to a dark shade (up to 9 or 13), depending on the welding arc’s intensity.

- This range lets me work comfortably in different welding conditions, always with the right level of protection.

- When I stop welding, the lens returns to its lighter state, allowing me to see my workspace clearly.

Polarization Filters Reduce Glare

Glare can make it hard to see the weld pool, but polarization filters inside the auto darkening lens help solve this problem. These filters block light waves that vibrate in certain directions, reducing the intensity of visible light and cutting down on glare. I find that this makes it much easier to focus on my work and see fine details.

The polarization filters work together with the liquid crystal cells, but they remain static. They always reduce glare, no matter what shade the lens is set to. This combination gives me a clear, comfortable view while welding.

Auto Darkening Lens Activation Process

Detecting the Welding Arc

When I start welding, I rely on my helmet’s sensors to recognize the welding arc instantly. These sensors, usually two to six in number, sit around the viewing area and pick up the intense light from the arc. I have noticed that even in bright environments, such as outdoors in sunlight, my helmet can still detect the arc accurately. Some advanced helmets use electromagnetic sensors for even better detection. The sensors do not react to ordinary light in the workshop or sunlight. Instead, they differentiate the unique brightness and spectrum of the welding arc from other sources. This means I do not have to worry about false triggers or missed activations.

The sensors send a signal to the helmet’s electronic control unit, which then activates the auto darkening lens. This process ensures that my eyes only get protected when it is truly necessary, and I can trust the helmet to work in any position—even if something blocks part of my view.

Instant Darkening Response

As soon as the sensors detect the welding arc, the helmet’s electronic system sends a signal to the auto darkening lens. The lens uses liquid crystal display (LCD) technology to change from a light to a dark shade almost instantly. I have experienced this rapid shift firsthand. The lens typically darkens within 0.1 to 0.5 milliseconds, depending on the helmet’s quality. This speed is so fast that my eyes never feel the effects of the arc’s initial flash. When I stop welding, the sensors notice the absence of the arc and the lens returns to its clear state just as quickly. This immediate response keeps my vision comfortable and my eyes safe throughout the welding process.

Speed and Reliability of Protection

I value the reliability of my auto darkening lens, especially during long welding sessions. Manufacturers test these helmets to meet strict safety standards, such as ANSI Z87.1, which requires laboratory validation of switching speeds and shade settings. Top-end helmets can switch from light to dark in as little as 1/25,000 of a second. My helmet also lets me adjust sensitivity and delay controls, so I can fine-tune how quickly the lens reacts and how long it stays dark after welding stops. Multiple sensors provide redundancy, so even if I work in awkward positions or block some sensors, the helmet still protects my eyes. Power sources like lithium batteries and solar cells undergo rigorous testing to ensure consistent performance. I trust my helmet to deliver reliable protection every time I weld.

Tip: Always check your helmet’s sensitivity and delay settings before starting a new welding project. Proper adjustment ensures the lens responds perfectly to your working conditions.

Continuous UV/IR Safety

Even when the lens appears clear, I know my eyes remain protected. The auto darkening lens contains special filters that block 99.9% of harmful ultraviolet (UV) and infrared (IR) radiation at all times. This permanent protection reduces the risk of eye injuries, such as arc flash, whether I am welding or just preparing my workspace. The lens uses advanced materials and technology to ensure that UV and IR rays never reach my eyes, regardless of the lens’s shade.

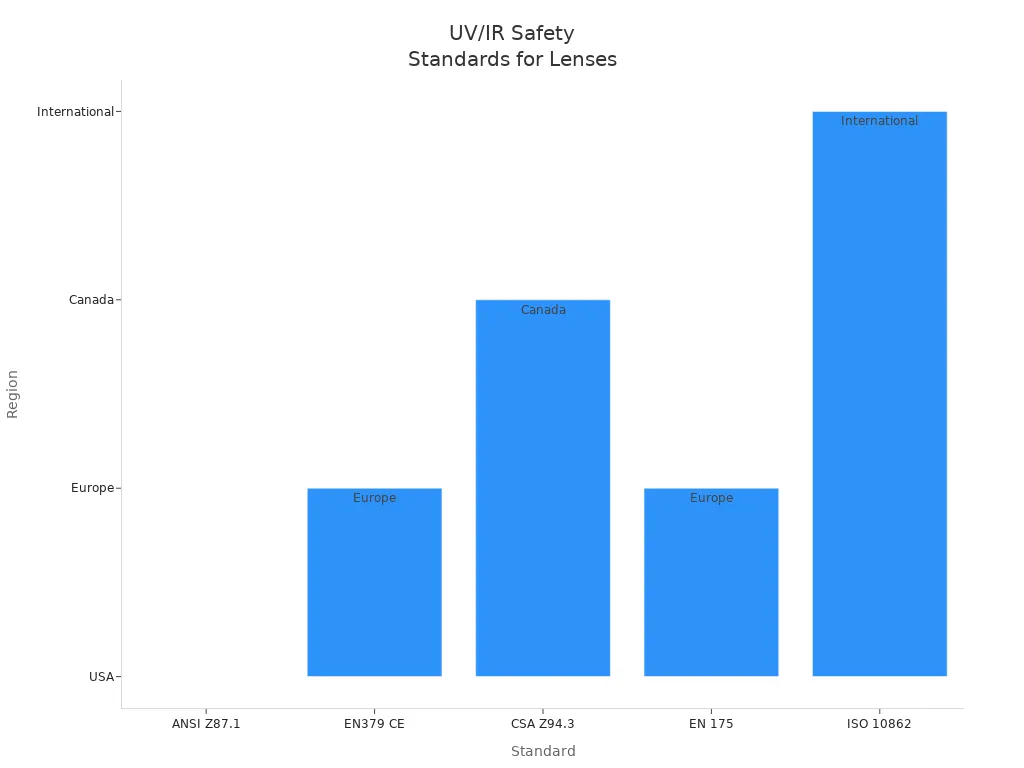

I always look for helmets that meet international safety standards. These certifications guarantee that my helmet provides continuous UV/IR safety, no matter the welding conditions.

| Standard | Region | Key UV/IR Safety Features |

|---|---|---|

| ANSI Z87.1 | USA | Ensures protection against UV and IR radiation, impact resistance, and optical clarity. |

| EN379 CE | Europe | Certifies auto-darkening filters for consistent UV/IR protection and lens clarity during welding. |

| CSA Z94.3 | Canada | Covers UV radiation protection, impact resistance, and lens durability. |

| EN 175 | Europe | Focuses on radiation protection (UV/IR), helmet durability, and optical performance. |

| ISO 10862 | International | Sets global guidelines for UV/IR protection, optical clarity, and helmet durability. |

With these features and certifications, I feel confident that my auto darkening lens keeps my eyes safe from harmful radiation at all times.

Checking Auto Darkening Lens Functionality

How to Test Your Lens

Before I start welding, I always check my helmet to make sure it works properly. I follow a few simple steps to test the lens:

- I press the TEST button on the helmet if it has one. The lens should darken, and I can check the battery status at the same time.

- I step into bright sunlight and watch for the lens to darken quickly. This shows the sensors respond to intense light.

- I use a lighter to create a small spark near the sensors. The lens should react and darken just like it would during welding.

- I hold the helmet under a bright fluorescent light to see if the lens activates.

- Sometimes, I use a TV remote control. I point it at the sensors and press a button. The lens should darken if the sensors pick up the infrared signal.

Tip: I always make sure grind mode is off and sensitivity settings are correct before testing.

Signs of Malfunction

I stay alert for any signs that my helmet might not be working right. Some common issues include:

- The lens does not darken when I strike an arc. Dirt or smoke might block the sensors.

- I see uncomfortable brightness or afterimages after welding. This can mean the lens did not darken enough.

- The lens flickers or fades, which often points to low battery or a worn-out filter.

- I notice a blurry or distorted view, usually caused by dirt or scratches.

If I spot any of these problems, I stop welding and check my helmet right away.

What to Do If the Lens Fails

When my lens fails, I follow a maintenance routine to restore safety and performance:

- I clean the cover lens with a soft, lint-free cloth and a mild cleaner. I avoid harsh chemicals.

- I remove dust using compressed air and gently wipe the auto-darkening filter.

- I inspect the lens for scratches or cracks. If I find damage, I replace the lens immediately.

- I check and replace the batteries if the lens flickers or does not darken.

- I store my helmet in a cool, dry place and inspect all components before each use.

Regular cleaning and careful handling help me keep my helmet in top condition and my eyes protected.

I trust my auto darkening lens to keep my eyes safe every time I weld. Recent advancements include electromagnetic arc sensing, faster lens response, and improved comfort.

- I always check my helmet before use.

- Regular maintenance and inspections help me avoid lens failure and ensure continuous UV/IR protection.

FAQ

How often should I replace my auto darkening lens?

I check my lens before every use. If I see scratches, cracks, or slow response, I replace it immediately to ensure my eyes stay protected.

Can I use my auto darkening helmet for grinding?

I switch my helmet to grind mode before starting. This setting prevents the lens from darkening, giving me a clear view while I grind metal.

What certifications should I look for in a welding helmet?

I always look for ANSI, CE, or CSA certifications. These standards guarantee reliable UV and IR protection, impact resistance, and optical clarity.

Post time: Jul-30-2025