TynoWeld sets a new standard with its auto-darkening welding helmet. The advanced lens technology delivers rapid switching speed and clear vision. Welders experience less eye strain and greater accuracy during every project. Professionals gain reliable protection and comfort for long hours, while hobbyists benefit from user-friendly controls. Safety certifications and durable materials make TynoWeld a trusted choice for anyone seeking top-tier performance.

Key Takeaways

- TynoWeld helmets switch from clear to dark in just 0.25 milliseconds, protecting eyes quickly from harmful arc light and reducing strain.

- Dual arc sensors ensure reliable detection of welding light, keeping the lens dark even if part of the view is blocked.

- Adjustable sensitivity and delay controls let welders customize the helmet for different welding tasks, improving comfort and safety.

- The helmet offers top optical clarity with true color view, reducing eye fatigue and helping welders see details clearly.

- Lightweight, ergonomic design and full safety certifications make the helmet comfortable for long use and protect welders from injuries.

Advanced Auto-darkening Welding Helmet Technology

Ultra-fast Lens Switching Speed

TynoWeld’s auto-darkening welding helmet stands out with its ultra-fast lens switching speed. The lens transitions from clear to dark in just 0.25 milliseconds (1/25,000 second), which is among the fastest in the industry. This rapid response protects the welder’s eyes from sudden bursts of intense arc light, ultraviolet, and infrared radiation. The quick lens darkening not only prevents arc eye and retina burns but also allows welders to maintain clear vision throughout the welding process.

| Specification Aspect | Details |

|---|---|

| Model | TC108 |

| Switching Speed | 0.25 milliseconds |

| Compliance Standards | CE EN175 & EN379, ANSI Z87.1, CSA Z94.3 |

| Description | Auto-darkening filter changes from clear to dark state automatically when arc is struck |

Industry studies confirm that ultra-fast lens switching speeds significantly enhance user safety. Welders experience less eye strain and avoid the need to lift the helmet repeatedly, which improves weld quality and reduces neck fatigue. The TynoWeld helmet’s advanced technology ensures welders can focus on precision and productivity without compromising safety.

| Aspect | Summary |

|---|---|

| Lens Switching Speed | Ultra-fast darkening in microseconds (e.g., 33 microseconds) or 1/25,000 second |

| User Safety | Shields eyes from arc light, UV, and IR, preventing arc eye and retina burns |

| Weld Quality | Maintains clear vision, reduces helmet lifting, improves precision, and lowers neck strain |

| Adjustable Controls | Sensitivity and delay settings optimize comfort and protection for various tasks |

| Additional Safety Notes | Protects against sparks, spatter, and heat, reducing risk of burns and vision damage |

Dual Arc Sensors for Reliable Detection

TynoWeld equips its auto-darkening welding helmet with dual arc sensors, ensuring reliable detection of the welding arc in all conditions. These sensors detect the bright light from the arc and trigger the lens to darken instantly. Dual sensors provide several advantages over single sensor systems:

- Enhanced sensitivity control for different welding environments.

- Consistent performance even if part of the lens is blocked by an obstacle or the welder’s hand.

- Reliable activation across all welding types and positions, including tricky or obstructed angles.

Multiple sensors increase detection accuracy, ensuring the lens darkens appropriately and consistently. This reduces eye strain and discomfort, especially during long welding sessions. The helmet’s design maintains consistent protection, allowing welders to work confidently in various applications.

Tip: Dual arc sensors help maintain uninterrupted protection, even when the welder moves or the arc is partially obscured, supporting workflow efficiency and safety.

Adjustable Sensitivity and Delay Controls

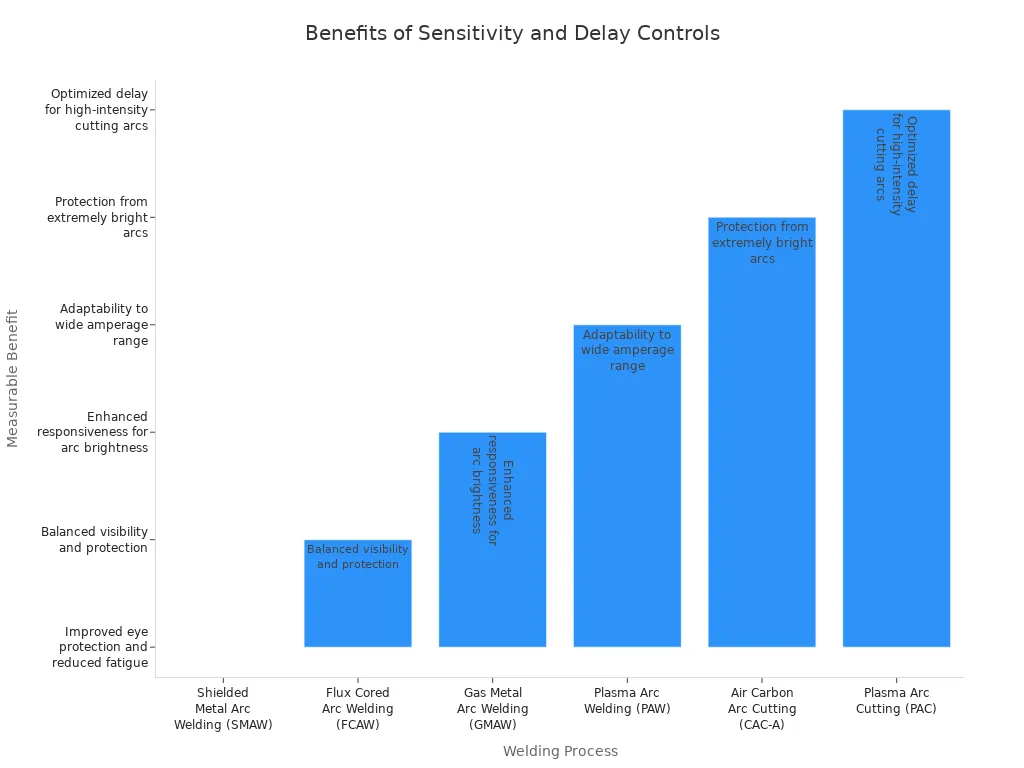

TynoWeld’s auto-darkening welding helmet features adjustable sensitivity and delay controls, allowing welders to tailor the helmet’s response to specific tasks and environments. Sensitivity controls determine how quickly the helmet reacts to the arc’s brightness, while delay controls set how long the lens remains dark after the arc stops. This flexibility provides measurable benefits for different welding processes:

| Welding Process | Arc Current Range | Recommended Sensitivity | Recommended Delay Setting | Measurable Benefits |

|---|---|---|---|---|

| Shielded Metal Arc Welding (SMAW) | Below 60A to 550A | Medium to High | Medium | Improved eye protection and reduced fatigue |

| Flux Cored Arc Welding (FCAW) | Below 60A to 500A | Medium | Medium | Balanced visibility and protection |

| Gas Metal Arc Welding (GMAW) | Below 50A to 500A | Medium to High | Medium | Enhanced responsiveness for varying arc brightness |

| Plasma Arc Welding (PAW) | Below 20A to 800A | High to Low | Short to Long | Adaptability to wide amperage range |

| Air Carbon Arc Cutting (CAC-A) | 0A to 1000A | High to Low | Short to Long | Protection from extremely bright arcs |

| Plasma Arc Cutting (PAC) | 300A to 800A | Medium to Low | Short to Long | Optimized delay for high-intensity cutting arcs |

TynoWeld helmets offer digital sensitivity adjustment from low to high and delay times ranging from 0.2 to 1.0 seconds. This range matches or exceeds leading brands, providing welders with the flexibility to optimize protection and comfort for any welding scenario. The helmet’s variable shade range and advanced controls ensure welders can adapt quickly to changing tasks, reducing eye fatigue and enhancing overall productivity.

Superior Optical Clarity and True Color View

High Optical Class Rating

TynoWeld helmets deliver industry-leading optical clarity with a 1/1/1/1 optical class rating. This rating, the highest available under EN379 standards, ensures welders experience minimal distortion, consistent light transmission, and a clear view from every angle. Many premium helmets on the market offer a 1/1/1/2 rating, which is professional but slightly below TynoWeld’s top-tier clarity. The table below highlights how TynoWeld compares to other premium models:

| Feature | TynoWeld TN15-ADF8610 | Typical Premium Helmet |

|---|---|---|

| Optical Class Rating | 1/1/1/1 (highest in industry) | 1/1/1/2 |

| True Color Technology | Yes | Yes |

| Standards Met | CE, ANSI, CSA | CE, ANSI, CSA |

A high optical class rating provides several advantages:

- Welders see the arc and workpiece clearly, without image distortion.

- Clearer vision reduces eye fatigue and supports longer, more comfortable work sessions.

- Precision improves, resulting in higher weld quality and fewer errors.

- Helmets with lower ratings may cause uneven shading and eye stress, impacting productivity.

HD TrueColor Technology

TynoWeld integrates HD TrueColor technology into its auto-darkening welding helmets. This innovation removes the traditional green tint, allowing welders to see the work area in natural, vivid colors. The result is a more accurate perception of the weld puddle, base material, and arc. Competing brands, such as Optrel and Lincoln, also use advanced lens technologies to achieve similar results. Welders using these helmets report crystal-clear vision and reduced tint, which helps them distinguish subtle details during TIG, MIG, or stick welding. TynoWeld’s TrueColor technology ensures welders maintain control and accuracy, even during complex tasks.

Reduced Eye Strain for Precision Work

Reduced eye strain stands as a key benefit of TynoWeld’s superior lens technology. The true-color lenses and high optical clarity allow welders to focus on their work for extended periods without discomfort. This comfort translates directly into higher productivity, as welders can complete more tasks without needing frequent breaks. Enhanced color recognition and visual detail also lower the risk of mistakes, supporting consistent, high-quality results. By minimizing eye fatigue, TynoWeld helmets help welders maintain precision and efficiency throughout every project.

Comfort and Ergonomics in Auto-darkening Welding Helmets

Lightweight Polypropylene Construction

TynoWeld engineers its helmets with lightweight polypropylene, creating a balance between durability and comfort. The helmet weighs only 16.22 ounces, making it easy to wear for long periods. This lightweight construction reduces neck strain and helps welders avoid fatigue during extended sessions. The shell, made from high-impact thermoplastic, withstands harsh environments while remaining comfortable. Many welders notice that a lighter helmet allows them to focus on their work without distraction.

- Lightweight design reduces neck strain, enabling longer use without discomfort.

- The helmet’s weight distribution prevents fatigue during prolonged welding sessions.

- Durable materials ensure the helmet stands up to daily use in demanding settings.

Ergonomic Design for Extended Use

TynoWeld prioritizes ergonomic design to support welders through long shifts. The helmet features a contoured shape that fits naturally around the head and neck. Adjustable straps and a padded headband provide a secure, snug fit. This ergonomic construction minimizes pressure points and helps distribute weight evenly. Welders benefit from reduced strain on the neck and shoulders, which supports endurance and productivity. Ventilation systems help keep users cool, even during intense welding tasks.

Note: Comfort features are critical for prolonged welding sessions, enhancing user endurance and overall satisfaction.

Customizable Headgear Fit

Every welder has unique preferences for fit and comfort. TynoWeld addresses this need with a 5-point adjustable geared headband. The headgear allows users to fine-tune the fit for maximum stability and comfort. A sweatband mechanism keeps moisture away, ensuring a dry and comfortable experience. Padded headgear further enhances comfort, making the helmet suitable for all-day wear. The customizable fit ensures the auto-darkening welding helmet stays securely in place, even during complex movements.

- Adjustable straps and headgear allow a secure, customized fit.

- Padded headgear ensures a snug and comfortable fit.

- Customization options help welders maintain focus and reduce distractions.

Safety and Durability Features

Comprehensive Safety Certifications (CE, ANSI, CSA, AS/NZS)

TynoWeld helmets stand out for their adherence to international safety standards. Each helmet meets or exceeds CE, ANSI, CSA, and AS/NZS certifications, which represent the highest benchmarks in the welding industry. These certifications guarantee protection against ultraviolet and infrared radiation, mechanical hazards, and optical risks. The table below summarizes the key certifications and their coverage:

| Certification Type | Details |

|---|---|

| CE | EN175 & EN379 standards |

| ANSI | Z87.1 standard |

| CSA | Z94.3 standard |

| AS/NZS | 1337.1 & 1338.1 standards |

| Optical Class | 1/1/1/2 (high visual clarity) |

| UV/IR Protection | Up to DIN16 at all times |

| Switching Time | 1/25000 seconds |

TynoWeld’s commitment to quality includes at least five inspections per helmet, from raw material selection to final packaging. This rigorous process ensures consistent reliability and performance. Professional welders worldwide trust TynoWeld helmets for their proven safety and global compliance.

Full Face and Neck Protection

Welding exposes users to a range of hazards, including flying debris, sparks, and intense radiation. TynoWeld helmets provide full face and neck coverage, reducing the risk of injuries such as ocular trauma, thermal burns, and radiation damage. Studies show that welding accounts for up to 33% of compensable eye injuries in the workplace. Comprehensive protection shields not only the eyes but also the entire face and neck, safeguarding welders and nearby assistants from harm.

- Full coverage design blocks flying particles and hot slag.

- Extended neck guard protects against burns from UV radiation and sparks.

- Multi-layer construction resists impact, heat, and hazardous light.

Note: Proper use of a full-coverage helmet, along with protective clothing, significantly lowers the risk of welding-related injuries.

Impact-resistant and Long-lasting Materials

TynoWeld constructs its helmets from impact-resistant materials such as carbon fiber and high-grade polypropylene. These materials offer superior durability compared to standard plastics. The helmet’s robust shell withstands harsh impacts, heat, and daily wear, making it ideal for demanding industrial environments. Users consistently rate TynoWeld helmets highly for their innovative design and long service life.

- Carbon fiber and polypropylene provide lightweight strength.

- Enhanced resistance to impacts and high temperatures.

- Premium materials ensure longevity and reliability.

The auto-darkening welding helmet from TynoWeld combines advanced safety features with durable construction, delivering dependable protection for professionals and hobbyists alike.

Versatility and Innovative Adjustability

Multiple Operating Modes (Weld, Cut, Grind)

TynoWeld helmets deliver exceptional versatility through multiple operating modes. Users can select from dedicated settings for welding, cutting, and grinding. This flexibility allows welders to adapt quickly to different tasks without changing equipment. The helmet supports a wide range of welding processes, including TIG, MIG, and MMA. Adjustable shade levels control how dark the lens becomes during welding. Sensitivity settings determine how easily the sensors detect light, while delay time adjusts how long the lens remains dark after welding stops. These features enable welders to fine-tune their helmets for various techniques and environments, increasing productivity and convenience.

- Adjustable shade level for optimal visibility

- Sensitivity setting for precise arc detection

- Delay time adjustment for comfort and safety

- Dedicated modes for welding, cutting, and grinding

Tip: Switching between modes helps welders maintain efficiency and safety across different applications.

Solar and Battery Power System

TynoWeld integrates a dual power system into its auto-darkening welding helmet. The helmet uses both solar cells and a replaceable lithium battery. Solar cells extend battery life by harnessing ambient light, reducing the need for frequent battery changes. The lithium battery ensures reliable performance during long work sessions. A low battery alarm and automatic self-check function help users maintain optimal helmet operation. This combination guarantees continuous protection and minimizes downtime, even in demanding industrial environments.

OEM Customization Options

TynoWeld stands out for its extensive OEM customization options. Clients can personalize helmets with custom decals, colors, and logos, aligning products with their brand identity. Personalized branding services help businesses create distinctive products that reflect their values and aesthetics. TynoWeld’s engineering team collaborates with clients to develop innovative helmets tailored to specific needs. Strong after-sales support and over 30 years of manufacturing experience ensure high-quality, reliable products.

| Manufacturer | Customization & Flexibility | Client Satisfaction Highlights |

|---|---|---|

| TynoWeld | Custom decals, colors, logos, handcrafted design, adjustable headbands | Highly rated for craftsmanship, comfort, and style |

| Pipeliners Cloud | Custom lenses, fasteners, versatile options | Positive feedback for adaptability and user-friendliness |

| CMR Fabrications | Limited customization, focus on lightweight design | Praised for innovation and protection |

| Pancake Welding Hood | Minimal customization, focus on comfort | Praised for practicality and comfort |

Note: TynoWeld’s customization flexibility and strong client support make it a preferred choice for businesses seeking unique, branded welding solutions.

TynoWeld’s auto-darkening welding helmet stands out with advanced lens technology, superior optical clarity, and ergonomic comfort. Welders benefit from reliable protection, customizable fit, and versatile operating modes. Users consistently praise the product’s reliability, quality, and innovative features.

- Many customers highlight the attentive service and timely product updates.

- Professionals value the company’s strong business management and training.TynoWeld remains a trusted choice for welders seeking safety, comfort, and cutting-edge performance.

FAQ

How fast does the TynoWeld auto-darkening lens react to welding arcs?

The lens switches from light to dark in just 1/25,000 second. This rapid response protects the welder’s eyes from harmful flashes and ensures continuous comfort during work.

Can users adjust the helmet for different welding tasks?

Yes. TynoWeld helmets offer adjustable sensitivity, delay controls, and multiple operating modes. Welders can easily switch between welding, cutting, and grinding for maximum versatility.

What certifications does the TynoWeld welding helmet have?

TynoWeld helmets meet CE, ANSI, CSA, and AS/NZS standards. These certifications guarantee reliable protection and compliance with international safety requirements.

Is the helmet comfortable for long-term use?

The helmet features lightweight polypropylene construction and ergonomic design. Welders experience reduced neck strain and improved comfort, even during extended shifts.

Does the helmet support custom branding or colors?

TynoWeld provides OEM customization options. Companies can add logos, decals, or choose unique colors to match their brand identity.

Post time: Jul-16-2025